Average wall thickness of 0.30 mm for tubes and strips and 0.35 mm for plates

Extreme uniform moulds

In the design and development stage BIOplastics pays considerable attention to a strategy that provides maximum mould and manufacturing accuracy. We outline precise product specifications, minimize mould cavities and define product thresholds, resulting in superior and reproducible products with, in the case of (q)PCR vessels, an average wall thickness of 0.30 mm for tubes and strips and 0.35 mm for plates both with a maximum tolerance of 0.05 mm.

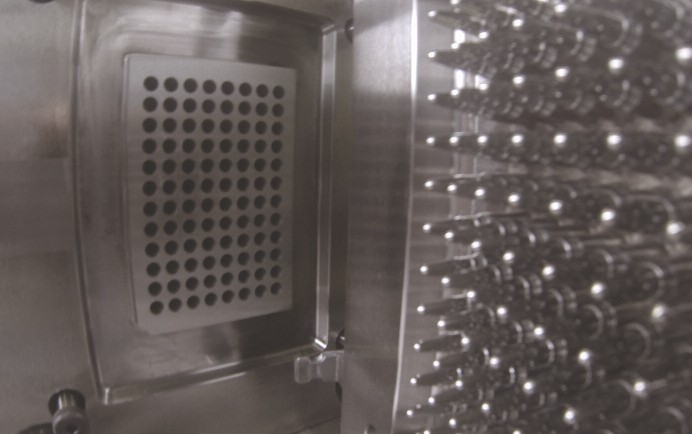

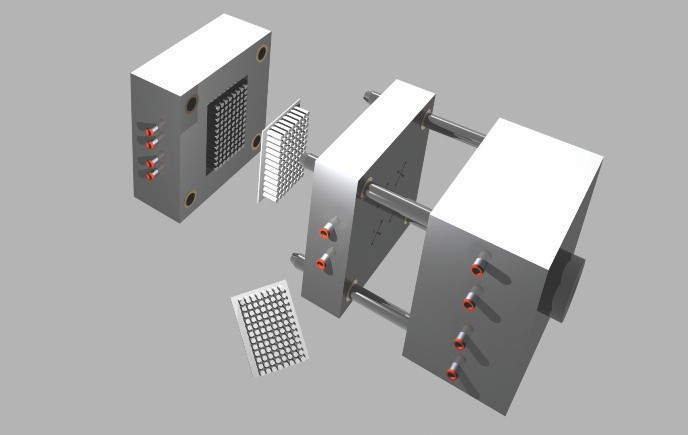

Injection moulding mould

Low-cavity moulds

To manufacture qPCR products, tips and tubes with the highest uniformity possible, a low-cavity mould should be used. This means only a few products are moulded during one cycle, after which the next few are moulded. Manufacturing from low cavity moulds is more time consuming, and is therefore more costly than using high multi-cavity moulds from which 32, 64 or even 128 products are released in one cycle. Competitor’s products are often manufactured using high-multi-cavity moulds and therefore differ severely in tolerances and quality due to this production parameter. Manufacturing parameters of low cavity moulds are better controllable versus high cavity moulds. Injecting the polymer into a high multi-cavity mould (pressure/temperature) increases mould imbalance issues and consequently product inconsistencies. This can result in batches of

products with extreme differences in wall-thickness, closure, orifice and fit, which will influence the reproducibility of your experiment. BIOplastics products are manufactured using single, low- and semi-low cavity moulds.

injection moulding mould

Extreme uniform manufacturing conditions

During the injection moulding process all physical, chemical and mechanical parameters are fine-tuned to obtain an Extreme Uniform plastic. Our superior in-house expertise allows us to determine the optimum balance between injection temperature of the polypropylene, the temperature of the mould itself during the cooling process, the injection time and the shrinkage time. We benefit from the knowledge of our sister companies CYCLERtest and GENO-tronics both well-known as manufacturer of the MTAS® and Driftcon® systems as well as provider of ISO17025 accredited (q)PCR cycler calibration (On-Site) services. BIOplastics has incorporated modified temperature multi-sensor systems to monitor and control moulds and injections moulding machines. The manufacturing process takes place in a dedicated cleanroom under GMP and hands-free conditions to ensure the absence of detectable levels of DNA, RNA, DNase, RNase, proteins, pyrogens and ATP.

Granules of medical grade polypropylene

Extreme uniform raw material blends

The polypropylenes used are of the highest medical grade polypropylene, which ensures no release of metals or other contaminants into the reaction mix. The carefully selected types of medical grade polypropylenes are “in house blended” to well-defined proprietary ratios. This specific fine tuned blend supports achieving the highest product and user performance properties. BIOplastics avoids the use of softeners, coatings and mould releasing agents.

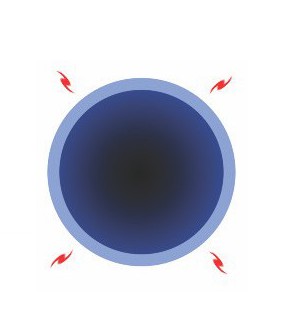

Non cracking (q)PCR tubes, strips and plates

The careful selection of different types of polypropylenes combined with extreme uniform wall thickness benefits BIOplastics products in a way that they do not crack easily. BIOplastics products can therefore withstand mechanical pressure and are impervious to possible small, microscopic, hairline cracks not visible with the naked eye.

So fact: EU products are strong, flexible and reliable and do not crack and are to easy handle!

Non-EU Tube

EU Tube

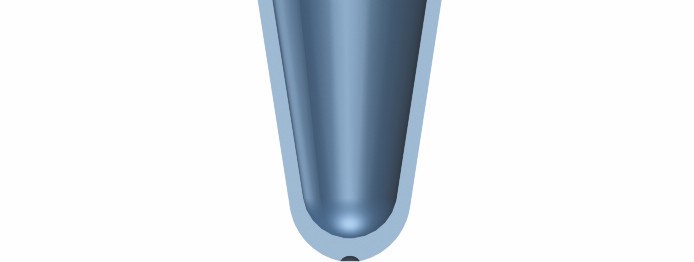

Cross section of a (q)PCR tube

Wall uniformity

Extreme Uniform wall thickness leads to even heating of the sample and more homogenous reaction conditions, leading to more reproducible results. Extreme Uniform wall thickness also leads to lower evaporation rates and therefore more consistent (q)PCR results. In case of optical detection by optical reading through side of the tubes, an extreme wall uniformity increases signal consistency.

Regular Profile Tube

Low Profile Tube

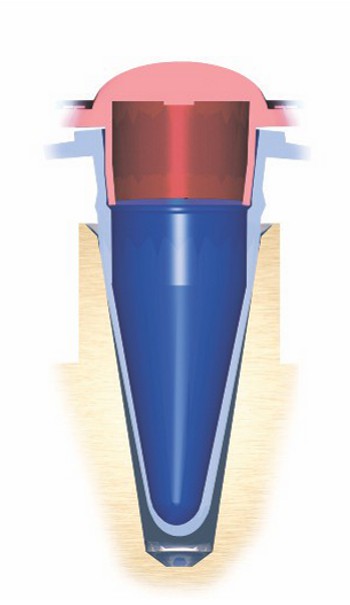

Wall thickness and gas tightness

Polypropylene (PP) is not completely gas tight and evaporation through the walls is inevitable.

Sample loss through the wall is proportional to the wall thickness and is also related to the type of PP.

BIOplastics BV designs its (q)PCR vessels with thin walls at the bottom, to allow optimal maximum heat transfer, and thicker walls at the top to minimize evaporation through the PP which consequently leads to more reproducible results.

Thin Wall Thickness of BIOplastics products is defined as, and measured, 3 mm from the bottom, where as:

Single tubes and strips:

0.30 mm ± 0.05 mm

Plates:

0.35 mm ± 0.05 mm

Tube angle, optimized for best fit

Different thermocycler brands and models have slightly different block well angles. BIOplastics uses its sister company’s (CYCLERtest) competence and knowledge of (q)PCR cyclers during the (q)PCR vessel design. BIOplastics (q)PCR vessels features a tube angle optimized to fit all main brands and models of (q)PCR thermocyclers, thus allowing maximum heat transfer for superior optimal and reproducible results.

Non-EU Tube

EU Tube

Low, regular and high profile products

In low profile tubes there is a smaller “air” volume above the reaction mix than in regular and high profile tubes. This allows less reaction mix to go into gas phase, leading to more concentration of the samples, less change in reaction conditions and therefore more reproducible results. Fast (q)PCR cyclers accept low profile, also called 0.1 ml tubes, strips and plates. Regular (q)PCR cyclers accept regular profile products whereas (q)PCR cyclers with height adjustable lids accept low, regular and high profile products (tubes, strip-tubes and plates).

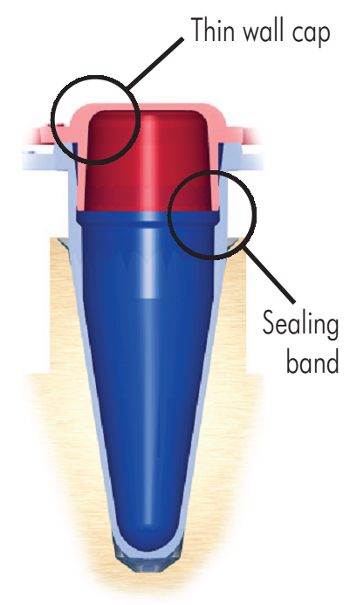

Easy opening and closure; cap design

Clever design and sealing bands around the tube closure points provide a leak-free seal, reducing evaporation and leading to more reproducible results. The superior sealing properties allows running (q)PCR reactions with volumes as low as 5 µl. The cap design allow minimum pressure for closure and opening which is highly appreciated by users and minimizes RSI risks.

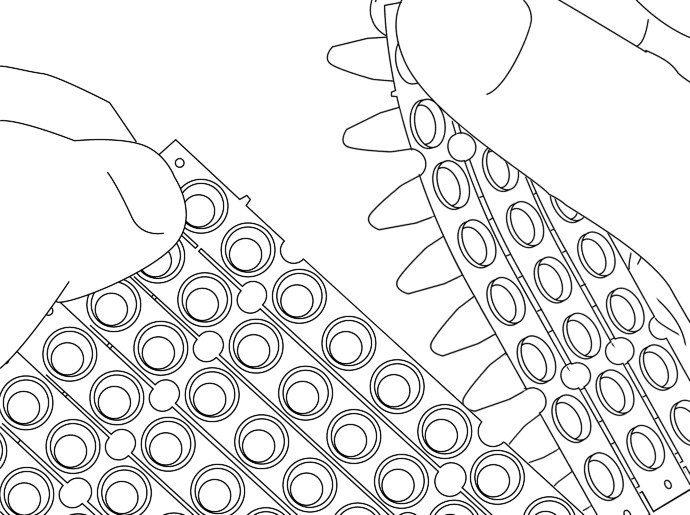

Required strips can be easily torn off from the Tear Off Strip 8-Tube Strip Mat

Tear Off 8-Tube Strip Mat

The Tear Off 8-Tube Strip Mat can be considered as a flexible plate composed of 12 robust 8-tube strips which are connected to each other by thin bands. Part of the “plate” or one of multiple robust 8-tube strips can be easily and effortlessly torn off. Enjoy the benefit of full flexibility and use the format required for your application or cycler. Tear Off 8-Tube Strip Mats as a whole or in partitions can be “clicked in” Shell Frame Grids. Why not use one format only and enjoy the benefit of full flexibility.

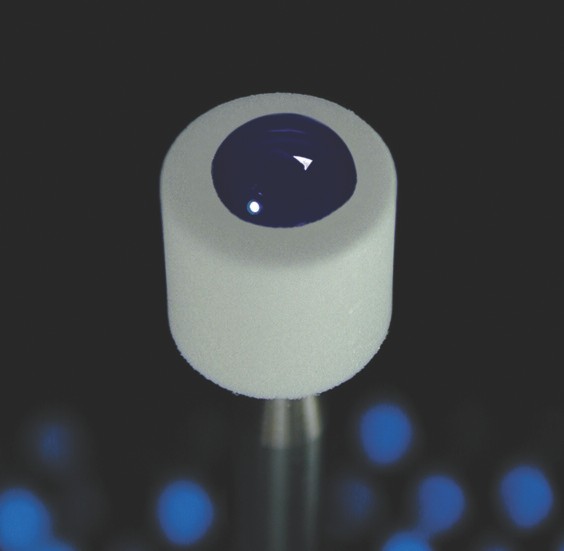

Indented qPCR Cap, the optical area is recessed into the optical cap surface to prevent “touching” the optical area.

qPCR caps and indented optical areas

The caps of EU tubes and cap-strips are designed to enable fluorescent signals to pass through to the optical detection unit of a Real-Time thermal cycler. For the closure of EU strips and plates BIOplastics offers a range of EU wide optical area cap strips along with the “Opti-Seal” adhesive seals. The EU optical caps strips have

maximum optical areas (12.6 mm

2) and the thickness of the “optical lens” is reduced to 0.30 mm, which minimize light absorption by the plastics. BIOplastics’ designers have positioned the “optical area” indented in the cap surface which prevents “touching” the optical area during the whole (q)PCR process. EU wide area optical cap strips can be used on any of the (q)PCR tubes, strips and plates. The robust design prevents any deformation; applying and removing these cap-strips is easy.

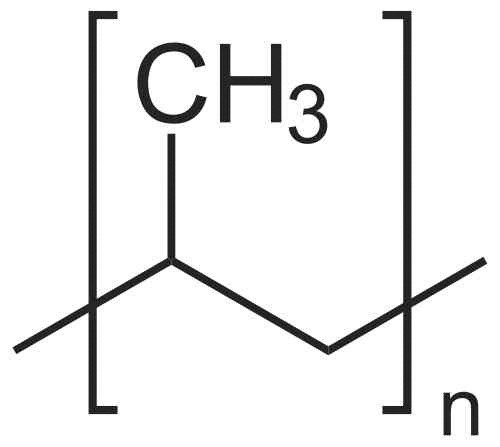

Basic structure of polypropylene (PP)

Type and blend of polypropylene, low binding characteristics

Although polypropylenes are chemically inert, they still exhibit charged groups, static properties and hydrophobic areas. Different types and blends of polypropylene therefore show differences in binding of ions like magnesium, proteins, DNA and other charged groups which may influence your results. BIOplastics offers 3 different blends of polypropylene, these being O-type, A-type and M-type material. The O-type material is an optimal material used in (q)PCR grade reaction vessels. O-type material is composed by blending multiple polypropylenes specifically designed for (q)PCR applications. A-type material resembles the classic polypropylene mix, has better chemical resistance properties when compared to O-type and is available for some of the (q)PCR reaction vessels. M-type material is a more robust material which is mainly used for

0.5 ml, 1.5 ml and 2 ml tubes and pipette tips.

For (q)PCR applications we recommend O-type material for optimal results, as it is non-binding and shows the highest thermal conductivity. O-type and M-type material blends are specifically selected for non-binding characteristics to DNA, RNA and proteins.

Indelible in product labeling of a 384 well plate using BIOplastics’ BPLPM technology

In product coding and labeling with BIOplastics BPLPM technology

BIOplastics innovated the incorporation of micro particles in (q)PCR and related products.

These BPLPM technology (BIOplastics particle mix) products are offered in a majority of (q)PCR products. BPLPM enables indelible IN PRODUCT labeling and identification. While others use stickers, ink, stamps, or dyes containing organic solutions, BIOplastics’ BPLPM technique results in a irreversible, non-removable, uniquely marked and coded product. No writing with markers, no removal of marks, no double identification numbers; just use the unique ID#, barcode or 2D code at the beginning of your process. Link the unique ID#, barcode or 2D code to your Lab LIMS system and samples. BPLPM technology is particularly useful for accredited labs in MDX and reduce risks of label mistakes and failures. Custom layouts and customized codes can be requested and applied to the required products by BIOplastics or even applied by your own institute if correct laser mark units are available. These types of unique coding prove to be appealing for (MDX) kit manufacturers to effectively trace products and applications. See also Chip incorporation (RFID)

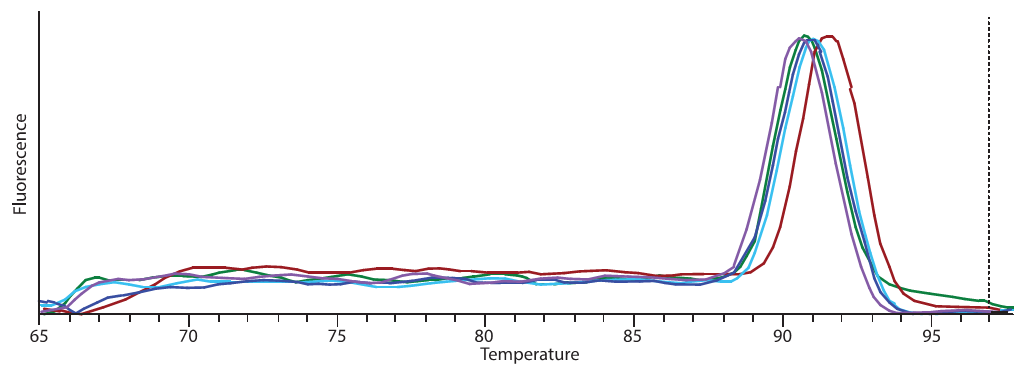

High Resolution Melting Curves (HRM) and regular melting curves

BIOplastics’ focus ensure maximum mould and manufacturing accuracy with precise product specifications, resulting in superior and reproducible products. BIOplastics’ (q)PCR vessels have a maximum tolerance of 0.05 mm. These extremely tight tolerances lead to extraordinary uniform and reproducible products.

Consequently, reproducible melting and high resolution melting curves, typically used in the post qPCR process, are generated using BIOplastics’ extremely uniform products. HRM curves can be normalized, i.e. “cycler fingerprint” adjusted, by using CYCLERtest® ISO17025 accredited cycler calibration services and calibration tools (www.cyclertest.com). See also page 151.

Shift of melting curves of one amplified fragment in qPCR.

Shift of melting curves of one amplified fragment in qPCR. Shift caused by difference in qPCR plates as well as un-uniformity of the qPCR cycler

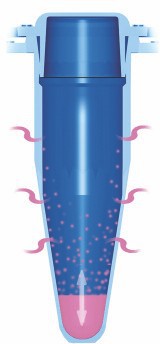

Gradient 18 micron filter with extended airflow and balanced optimal aerosol protection

Gradient filter in filtertips

The filter in a filtertip eliminates the formation of aerosols in the shaft of the pipette, since it blocks the air-to-liquid interface between the sample and the pipette shaft. This simple idea has evolved in numerous types and brands of filtertips and filter materials. Most filters are made of 3-dimensional cross-linked HMPE (Polyethylene), which is totally inert. The pore size should be smaller than 25 microns to generate a “reasonable protection” and not smaller than 14 microns to still allow an accurate airflow required when pipetting. The filtering capacity of a certain filter is defined as the ratio of filter length and pore size. The longer a filter is, the better it filters. This relation is almost linear. BIOplastics filters are the longest available in the market with a superior 18 micron pore size gradient whereas other suppliers use shorter length and 25 to 30 micron filters! By applying a gradient into the filter, BIOplastics’ filtertips have an extended airflow and a balanced optimal aerosol protection due to its pore size and filter length, with a minimum compromise of pipetting accuracy.

Pipette tips

BIOplastics tips have a very fine orifice for complete, reproducible pipetting. The pipette tips are extremely clear to allow content examination if required. Tips are extremely uniform, flexible and soft, to secure a good leak-free fit around with the shaft of the pipette. The soft, ultra-clear medical grade material also reduces RSI

since the force to attach and release the tip from the pipette is significantly reduced. The fine orifice assures reproducible pipetting. Tips marked with the beveled orifice icon have a special 45° beveled orifice to guide the ejection of the fluids even better. Furthermore the raw material used in pipette tips has very low binding

properties to biomolecules and has superior retention/recovery properties when pipetting ion-containing solutions.

Screw Cap Tubes (SCT)

BIOplastics’ smart secure closure technology results in superior screw cap tubes. The screw caps are designed in a way that the use of “old fashioned” rubber rings has become obsolete. The absence of a rubber ring assures that the closure is not affected when in contact with organic solvents nor that leakage occurs due to hardening and unbalanced shrinkage caused by low and high temperatures and pressure. The smart secure closure design allows frequent opening and closing, even in extreme conditions, without compromising the closure and also avoiding leakage (working range -200 °C -+100 °C). Screw Cap Tubes are available in low binding and extreme robust formats which even allow severe bead beating procedures.

Pipette tip with fine orifice for complete, reproducible pipeting

Unique coded tubes, strips and plates

Due to BIOplastics’ BPLPM technology, products can be individually and uniquely coded. These products are available for the qPCR product range as well as for micro centrifuge tubes and screw cap tubes. Each tube can have a unique ID#, 1D or 2D code. Specific codes or customized marking of any BIOplastics product are available on demand.

Unique coded tubes, strips and plates Image